POLYCRETE sewer pipe

Convincing quality

Creating the best products from high quality materials. We manufacture POLYCRETE® pipes exclusively through casting, in accordance with this guiding principle. Only this way can the recipes be tailored ideally to the application and homogenous mixtures be prepared. That is because the uniform, thorough mixing process and the mixing ratio of the raw materials we use determine the long term usage characteristics of the pipes.

The direct contact of the material and the casting formwork guarantees continuous smooth and high quality surfaces over the complete length of the pipe. These surfaces are then finished with an additional coating.

At the same time this manufacturing method allows each pipe the necessary time for curing in its perfect shape in the formwork with dimensional accuracy. Thus, precise joint dimensions are assured with uniform materials and without the need to fit additional external couplings made from other materials. If the joints are not cast, as with the egg profile pipes, the factory pre-assembles couplings made from GRP - a material with almost identical chemical behaviour in soil.

The integrated joints allow the quick and secure installation of the pipes. The pipe joints for POLYCRETE® sewer pipes are designed for pipelines operated without pressure and can withstand a test pressure of up to 2.4 bar, even under draw, angular deflection and shear loads. This also allows the use of the pipes in water protection zones.

The pipes comply with DIN 54815 as well as the international product standards EN 14636-1, ISO 18672-1 and ASTM D 6783-05. Their high quality is assured through the consistent implementation of the factory’s own production monitoring and the materials testing agency of North Rhine Westphalia, MPA NRW, continuously monitors the quality in accordance with the product standards.

Fitting lengths and rocker pieces for connection to shafts are also manufactured in the necessary short lengths in accordance with customer requirements. Whether in the planning phase or in concrete installation cases - our technical department will check the suitability of POLYCRETE® sewer pipes for your particular application. Verifiable static calculations are implemented in accordance with DWA worksheet A 127. We will gladly send you our sample specifications so you can take the right materials into account in any tenders.

Feel free to request the data sheet “Load data for POLYCRETE® sewer pipes acc. to DIN EN 14636-1 and ISO 18672-1” from us.

.

Specifications

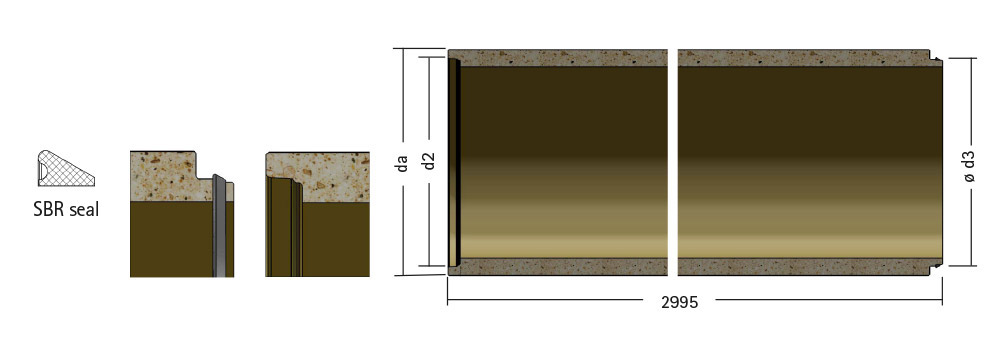

POLYCRETE® sewer pipes with bell socket DN 300 - DN 1000

| Internal diameter DN | External diameter da | Wall thickness s | Length L | Sleeve d2 | Pointed end d3 | Pipe weight |

|---|---|---|---|---|---|---|

| mm | mm | mm | m | mm | mm | kg/m |

| 300 | 382 | 33 | 3 | 382 | 364 | 90 |

| 400 | 498 | 41 | 3 | 498 | 480 | 145 |

| 500 | 614 | 49 | 3 | 614 | 596 | 210 |

| 600 | 726 | 55 | 3 | 726 | 708 | 280 |

| 700 | 835 | 65 | 3 | 835 | 812 | 390 |

| 800 | 951 | 74 | 3 | 951 | 928 | 500 |

| 900 | 1087 | 83 | 3 | 1087 | 1064 | 630 |

| 1000 | 1205 | 92 | 3 | 1205 | 1182 | 775 |

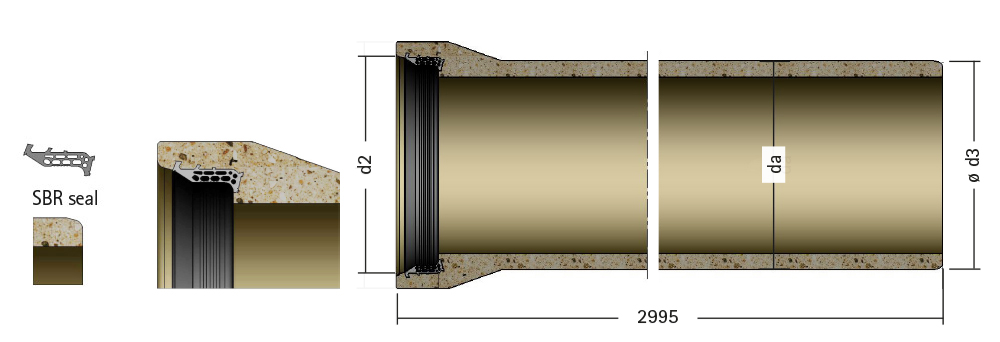

POLYCRETE® sewer pipes with rebate socket DN 1200 - DN 2000

| Internal diameter DN | External diameter da | Wall thickness s | Length L | Sleeve d2 | Pointed end d3 | Pipe weight |

|---|---|---|---|---|---|---|

| mm | mm | mm | m | mm | mm | kg/m |

| 1200 | 1420 | 110 | 3 | 1306 | 1284 | 1045 |

| 1400 | 1660 | 130 | 3 | 1529 | 1501 | 1440 |

| 1500 | 1774 | 1377 | 3 | 1632 | 1604 | 1625 |

| 1600 | 1890 | 145 | 3 | 1740 | 1712 | 1835 |

| 1800 | 2120 | 160 | 3 | 1955 | 1927 | 2270 |

| 2000 | 2350 | 175 | 3 | 2167 | 2136 | 2755 |

Brochure (PDF)

Brochure (PDF) Lastangabenblatt (PDF)

Lastangabenblatt (PDF) Werkstoffkennwerte (PDF)

Werkstoffkennwerte (PDF)